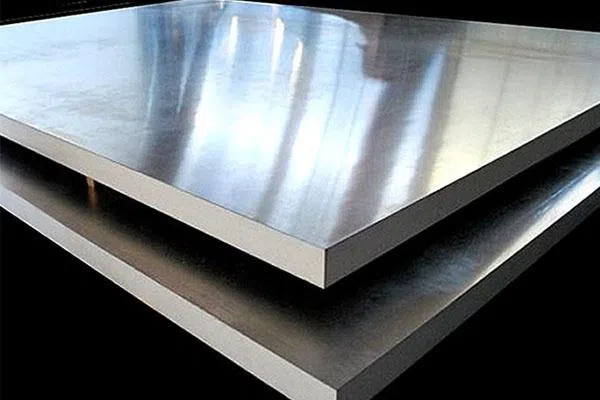

Today, aluminum plate manufacturers will introduce a pure aluminum plate for the proud love. Do you know what this is and the scope of its application? Let's take a look at it:

Pure aluminum plate is low in strength, but has excellent formability, surface treatment, weldability, and corrosion resistance. 1050 aluminum plate sheet is also a product in the pure aluminum plate series, and its chemical composition and mechanical properties are similar to those of the 1xxx series. It is basically replaced by 1060 aluminum plate sheet in current applications. The last two Arabic numerals of the 1050 series are 50. According to the international brand naming principle, the aluminum content must be above 99.5% to be qualified products. China's aluminum alloy technical standard (GB / T3880-2006) also clearly stipulates that the aluminum content of 1050 reaches 99.5%. Because it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is currently the most commonly used series in conventional industries.

Application range of pure aluminum plate

It is often used in daily necessities, lighting appliances, reflectors, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, appliances, stamping parts and other products. In some cases where high corrosion resistance and formability are required, but the strength is not high, chemical equipment is its typical use.

Chemical composition of pure aluminum plate

Aluminum Al: 99.50; silicon Si: 0.25; copper Cu: 0.05; magnesium Mg: 0.05; zinc Zn: 0.05; manganese Mn: 0.05; titanium Ti: 0.03; vanadium V: 0.05; iron Fe: 0.40; single: 0.03.

Mechanical properties of pure aluminum plate

Tensile strength σb (MPa): 110 to 145. Elongation δ10 (%): 3-15. Heat treatment specifications: 1) Complete annealing: heating at 390 ~ 430 ℃; depending on the effective thickness of the material, the holding time is 30 ~ 120min; cooling at 30 ~ 50 ℃ / h with the furnace to 300 ℃, and then air cooling. 2) Rapid annealing: heating 350 ~ 370 ℃; depending on the effective thickness of the material, the holding time is 30 ~ 120min; air or water cooling. 3) Quenching and aging: quenching 500 ~ 510 ℃, air cooling; artificial aging 95 ~ 105 ℃, 3h, air cooling; natural aging room temperature 120h

QR Code