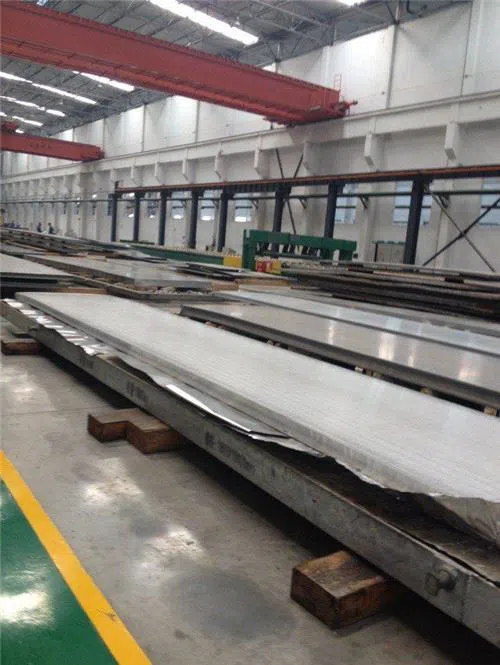

Aluminum plates, as the name implies, are plate-type materials made of aluminum or aluminum alloy materials. Or a plate-shaped aluminum product produced by heating, rolling, straightening or solid solution aging heat of a flat aluminum embryo.

The aluminum plate used in the construction include single-layer aluminum plates, composite aluminum plates and other materials. Generally, they are usually referred to as single-layer aluminum plates (also called single aluminum plates or pure aluminum plates), which are mostly used in architectural decoration projects. In recent years, single-layer aluminum plates are used in aluminum plate curtain walls. More common. The aluminum curtain wall is also a form of curtain wall. Simply speaking, the aluminum panel is used instead of the glass to make the curtain wall. The aluminum curtain wall is mostly used for wall covering and non-lighting walls. For example, the Guangzhou World Trade Center used the southwest aluminum processing plant sheet factory to process nearly 150 tons of aluminum plates with different curvatures, and the surface was electrostatically sprayed. Foreign aluminum panel curtain walls have always used single-layer aluminum panels. Single-layer aluminum sheets are generally made of pure aluminum sheets. The thickness of the aluminum plate is 3mm. In order to strengthen the strength of the aluminum plate, the ribs must be installed on the back of the aluminum plate (the existing manufacturer is uneasy). The ribs are made of thick aluminum strips. First, use a flash welder to put a screw cap. Welded on the back of the aluminum plate and then drilled the aluminum strips made of ribs into the screws and fixed them with screws. In order to reduce the weight of aluminum plates and increase the strength of aluminum plates, we use aluminum alloy plates, which are often made of aluminum plate pressed by No. 21 rust-proof aluminum code LF21. The thickness of the aluminum plate is reduced from the original 3mm to 2.5mm, and the strength of the alloy is about twice as high as that of the pure aluminum plate. The ribs are made of LF21 aluminum strip. The width of the strip is determined according to the surface of the aluminum sheet. It is generally 2-2.5mm thick and 10-25mm wide. Why should the back of the aluminum plate of the aluminum plate curtain wall be reinforced? When the external positive and negative pressure is applied, the aluminum plate will not be sunken, and the second will not bulge, thus avoiding the vibration sound of the aluminum plate curtain wall repeatedly vibrating inside and outside. If sound insulation is required, rock wool, slag wool or foaming treatment can be placed on the inside of the aluminum plate. The first aluminum plate manufacturer in China to produce aluminum curtain wall, Chongqing Southwest Aluminum Deep Processing Factory, which is a military manufacturer, can produce aluminum plates with a width of 2.8 meters. The surface treatment of the curtain wall aluminum plate can be divided into two methods, one is anodizing and the other is electrostatic spraying. The anodized oxide film is generally above 12μ, the color is only bronze and white, the color is monotonous, and the more serious disadvantage is that the color of each aluminum plate surface is different, and many pieces of curtain wall panels are combined to form a curtain wall overall effect. Very ugly. This shortcoming can be said to be impossible to eliminate, not caused by production technology, but because the aluminum plate is not made up of a batch number, chemical composition, there are small differences, plus the current density of the electrolytic cell during oxidation can not be exactly the same, so The color after oxidation is somewhat different, and the single sheet may not be obvious. If they are all arranged together, it is very obvious. Therefore, the surface treatment of the aluminum plate of the aluminum curtain wall must not be anodized.

Another method of surface treatment of curtain wall aluminum panels is electrostatic spraying. Spraying is divided into powder spraying and liquid spraying. The powder spraying materials are mainly composed of polyurethane, bulging resin, epoxy resin and other raw materials with high color retention pigments, and dozens of different colors of spray powder can be obtained. The sprayed powder is resistant to collision and abrasion. Under the impact of 50 kg, the aluminum plate is deformed, the sprayed layer has no cracks, no falling layer is intact, and it is resistant to dilute acid and mortar. The only shortcoming is the long-term exposure to ultraviolet light, which is prone to the difference in color between the yin and the yang. The spray powder produced by many domestic manufacturers has a very different weight. Some powders contain gold dust. After the powder is hung on the wall, it changes with the angle of sunlight. There are changes during the day and dusk, and the color depth of the wall varies. Use powder spray paint to attract attention. Liquid spray coating, fluorocarbon polymer spray coating, commonly known as fluorocarbon spray coating, is a fluorocarbon polymer resin used in the manufacture of lacquer oil. It is used as a metal topcoat. The combination with fluorine is the most stable molecular combination.

Since the single-layer aluminum plate is more easily bent and shaped than the honeycomb aluminum plate, it can better adapt to the changing endless decoration of the building exterior wall. It is generally considered that the single-layer aluminum plate is the best for the aluminum plate curtain wall material. It can get a variety of color sprayed surface, good strength, low cost and long life. If it is not in direct contact with steel, the aluminum plate will hang on the wall and will not fall off and corrode in 50 years. Life may be longer and match the life of the building.

The single-layer aluminum plate curtain wall is made of pure aluminum 3mm or LF21 2.5mm aluminum plate veneer. The single-layer aluminum plate is developed due to the development of electric bolt welding technology. The electric bolt welding realizes the reinforcement welding on the back of the single-layer aluminum plate veneer. Reinforced ribs, without destroying the aluminum panel finish, the single-layer aluminum sheet is easily bent into a complex shape, with high strength and long life (up to 50 years), so its appearance makes the aluminum panel curtain wall rich in processing form and installation structure. a lot of.

The single-layer integral stamping and forming aluminum sheet is made of a special processing of a single-layer aluminum sheet. It can be regarded as a special case of a single-layer aluminum sheet for the special-shaped aluminum panel wall surface used for the exterior molding of the building.

QR Code