Aluminum foil for air conditioning refers to foil used in air conditioners, and is a common type of air conditioner that uses aluminum foil, which includes domestic air conditioners, central air conditioners, air conditioners for cars, air conditioners for computer rooms, air conditioners for trains and food refrigeration equipment. Because the aluminum foil has good thermal conductivity, easy deformation, processing, light weight, low price, no pollution, etc., it has become the material of choice for air conditioning heat exchangers.

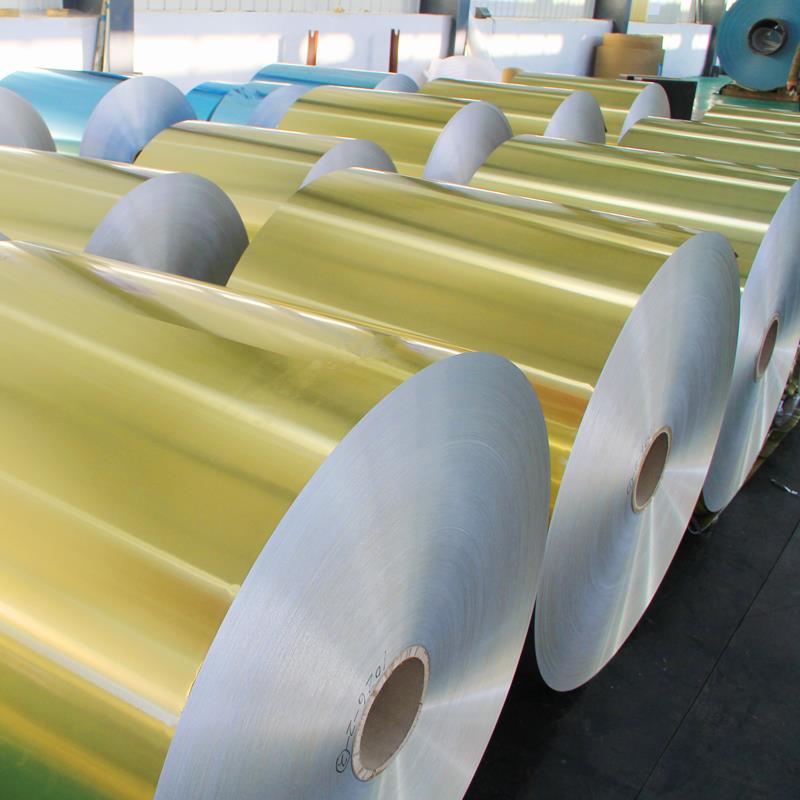

Currently, air conditioners are moving towards miniaturization, high performance and long life. Air conditioning heat exchangers have also evolved towards ultrathin and high strength. In the 1980s, the thickness of the heat exchanger was 0.15-0.2 mm, while the current thickness is only 0.09 to 0.15 mm. In addition, to improve the life of air conditioners, reduce energy consumption, improve ventilation quality and improve cooling performance, coated heat exchangers have been developed that have various functions. Typical corrosion-resistant heat transfer fins and surface hydrophilic heat exchangers, surface hydrophobic heat exchangers, mold heat exchangers, self-lubricating heat exchangers, etc. With the development of heat exchangers, aluminum sheets for air conditioners have also developed greatly. Today, thin aluminum sheets have higher heat exchange properties and are now used in air conditioners. The common grades are 8011 and 1145, and there are several tempering functions!

All aluminum does not corrode (except for atmospheric reasons). There is no contact with different metals, so there is no dielectric reaction.

Newer manufacturing techniques constantly weld aluminum to achieve uniform strength.

Aluminum coils are easier to recycle.

Aluminum coils are cheaper to transport.

Aluminum costs less than copper.

Technological advances in microchannel coils have made aluminum more viable, while significantly reducing the weight, size and refrigerant charge, while improving performance.

The government's tendency is to force manufacturers to meet the requirements of greater efficiency, so the surface area is getting larger. This caused many problems. Increases in refrigerant charge, larger equipment size, higher transportation costs and rapid restrictions on available installation areas compensate for the change in efficiency.

QR Code