Marine aluminum alloy according to the different manufacturing process can be divided into deformation of aluminum and cast aluminum alloy, due to marine aluminum alloy on the strength, corrosion resistance, weldability and other special requirements, so the choice of marine aluminum alloy aluminum - magnesium alloy , Aluminum-magnesium-silicon alloy and aluminum-zinc-magnesium alloy, of which 5xxx series of aluminum - magnesium alloy on the most widely used in ships, then, 5xxx series of marine aluminum alloy What are the characteristics of it?

5xxx series of marine aluminum alloy mainly are 5083,5086,5454. 6 series aluminum alloy in the seawater will occur the intergranular corrosion, so the ship superstructure use more. 7 series alloy shortcomings is poor corrosion resistance, so the use of limited. On the whole, 5 series of marine aluminum is currently the most widely used, the most promising aluminum products.

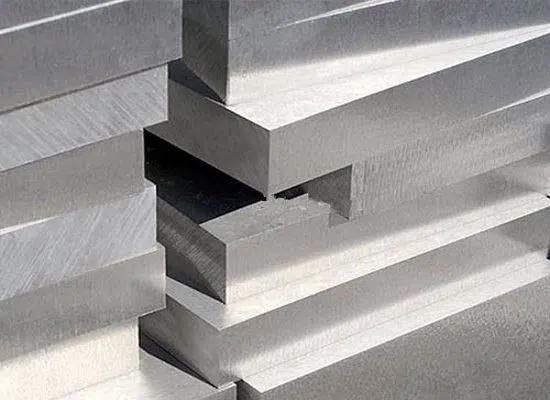

5083 aluminum alloy can be regarded as representative products of 5 series marine aluminum plate. The temper are O, H111, H112, H116, H321 and so on. The composition of 5083 aluminum alloy is aluminum aluminum: balance, silicon Si: ≤0.40, copper Cu: ≤0.10 , Magnesium Mg: 4.0 to 4.9, zinc Zn: ≤0.25 Mn Mn: 0.40 to 1.0 Titanium Ti: ≤ 0.15 Cr Cr: 0.05 to 0.25 Fe Fe: 0 to 0.400, 5083 Aluminum alloy has moderate strength, good corrosion resistance and good formability , High resistance to fatigue, generally used as the main structure of the hull. Others such as 5052,5086,5454,5456, etc., are also used in hull structures or pressure vessels, pipes, hulls and decks.

In general, the thickness of the use of the plate is determined by the hull structure, the ship's specifications and the use of parts, etc., from the perspective of the weight of the hull, the general use of sheet metal, but also should be considered in the use of time the depth of corrosion of the plate, Plate has more than 1.6mm sheet and above 30mm the plate. There are also some special specifications for the use of shipyard contracts. For non-slip, deck with pattern plate.

The characterisctics of 5xxx series marine aluminum alloy:

Classify | Aluminium Alloy | Temper | Chemical composition | Characteristics | Applications |

Used for Ship body | 5052 | O | Al :remainder Si: ≤0.25 | moderate strength, | upper structure, subsidiary |

5083 | O | Al :remainder Si :≤0.40 | typical welding aluminium alloy, | main structure of ship body | |

5086 | H32 | Al:remainder Si :≤0.40 | With good weldability and corrosion resistance | main structure of ship body | |

5454 | H32 H34 | Al:remainder Si :≤0.25 | Tensile strength is 22% higher than 5052, | ship structure, pressure | |

6061 | T4 T6 | Cu :0.15~0.4 Mn :0.15 | Heat treating corrosion resistant alloy, | Upper structure, clapboard | |

Used for outfitting | 1050 | H112 O H12 H24 | Al :remainder Si: ≤0.25 | with low tensile strength, good processability, | interior finish |

1200 | H112 O H12 H24 | Cu :≤0.50 Mn:≤0.50 | with low tensile strength, good processability, | interior finish | |

3003 | H112 O H12 | Al :remainder Si: ≤0.60 | Tensile strength is 10% higher than 1100, | interior finish, |

QR Code