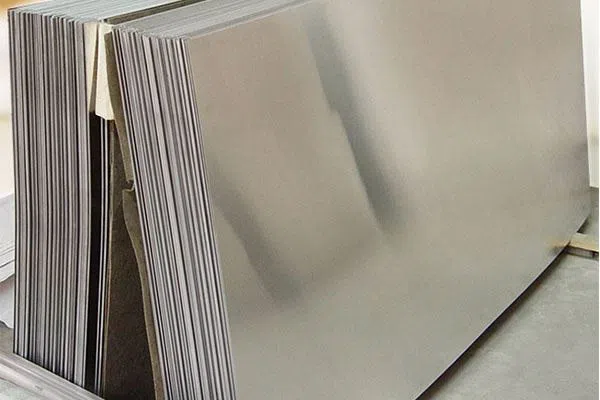

The 5052 aluminum sheet and 5754 aluminum sheet are Henan Henry's popular products. The product has high market acceptance, skilled processing technology, stable product performance, good molding processing performance and corrosion resistance. It is a widely used rust-proof aluminum. The product is in the trolley case, fuel tank material, liquid crystal back plate and tank body. Materials, door panels, high-voltage switch housings and other fields are widely used.

5052 aluminum sheet

5052 is an Al-Mg rust-proof aluminum alloy, which can not be heat-treated and strengthened. The chemical composition of the alloy is similar to that of 5A02 alloy, and the performance is basically the same as that of 5A02. The alloy has higher plasticity and lower strength, and its corrosion resistance and weldability are good. The alloy has poor machinability in the annealed state.

5052 Aluminum sheet is used for parts requiring good formability and corrosion resistance, high fatigue limit, good weldability, moderate static load, such as aircraft fuel and oil-filled conduits, fuel tanks, and various marine and ground equipment parts, cold stamping. Pieces, sheet metal work products, street lamp pillars; materials used as rivets or welding rods.

5754 aluminum sheet

The 5754 aluminum sheet is characterized by moderate strength, good corrosion resistance, weldability and ease of forming. It is a typical alloy in Al-Mg alloys. In foreign countries, 5754 aluminum alloy sheets of different heat treatment conditions are the main materials used in the automobile manufacturing industry (car doors, molds, seals) and canning industry.

5754 aluminum sheet is widely used in welding structures, storage tanks, pressure vessels, ship structures and offshore facilities, transportation tanks, as well as in applications requiring excellent machining performance, excellent corrosion resistance, high fatigue strength, high weldability and medium static strength.

Surface of 5754 aluminum sheet:

1. Surfaces are not allowed to have cracks, corrosion spots and traces of nitrate.

2. The surface shall be allowed to have peeling, air bubbles, surface roughness and local mechanical damage with a depth not exceeding 8% of the nominal thickness of the part where the defect is located, but the maximum depth of the defect shall not exceed 0.5 mm, and the total area of the defect shall not exceed the total area of the plate. 5%.

3. Allow the supplier to illuminate the profile longitudinally to a smooth surface.

4. Other requirements: There is a demand side and the supplier to develop their own

QR Code